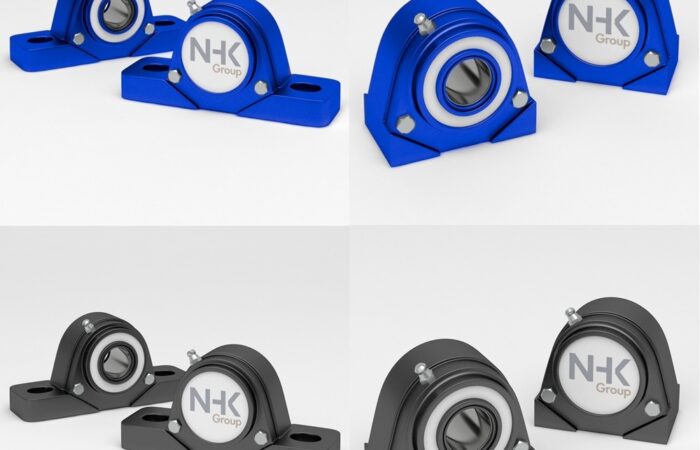

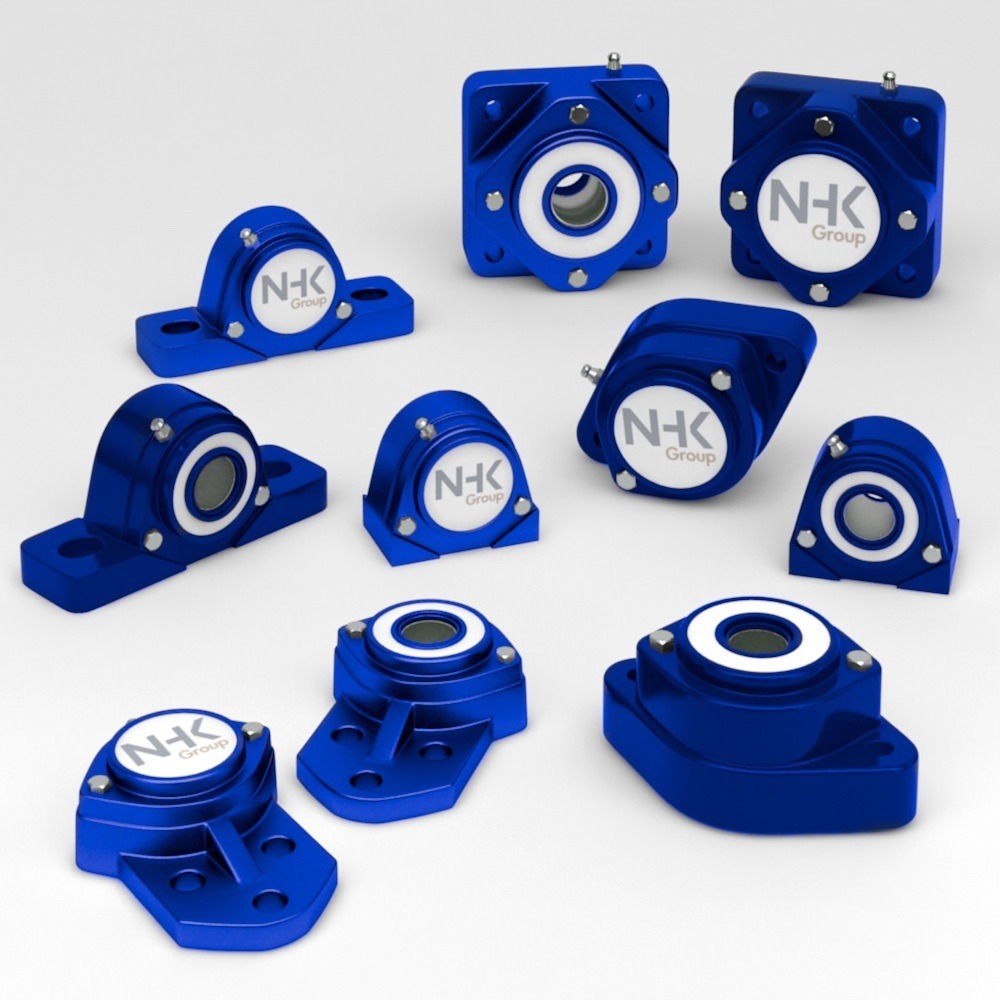

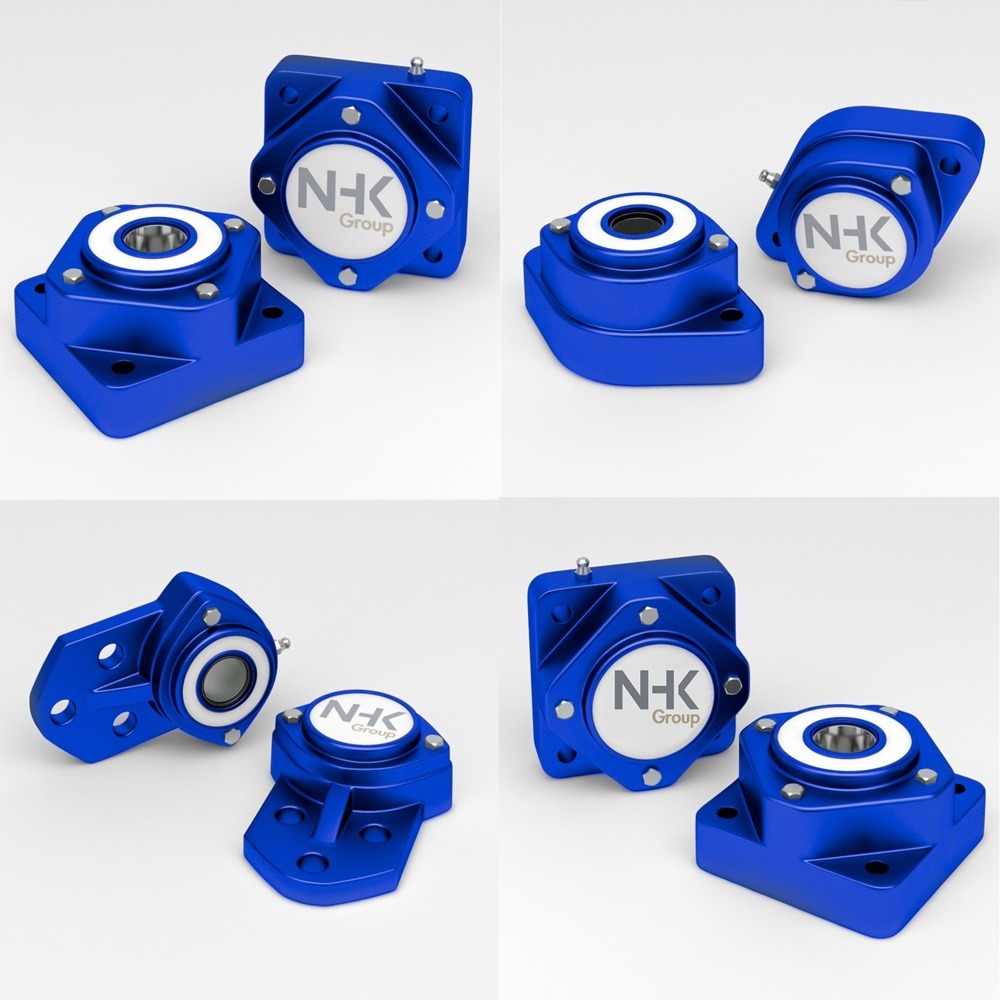

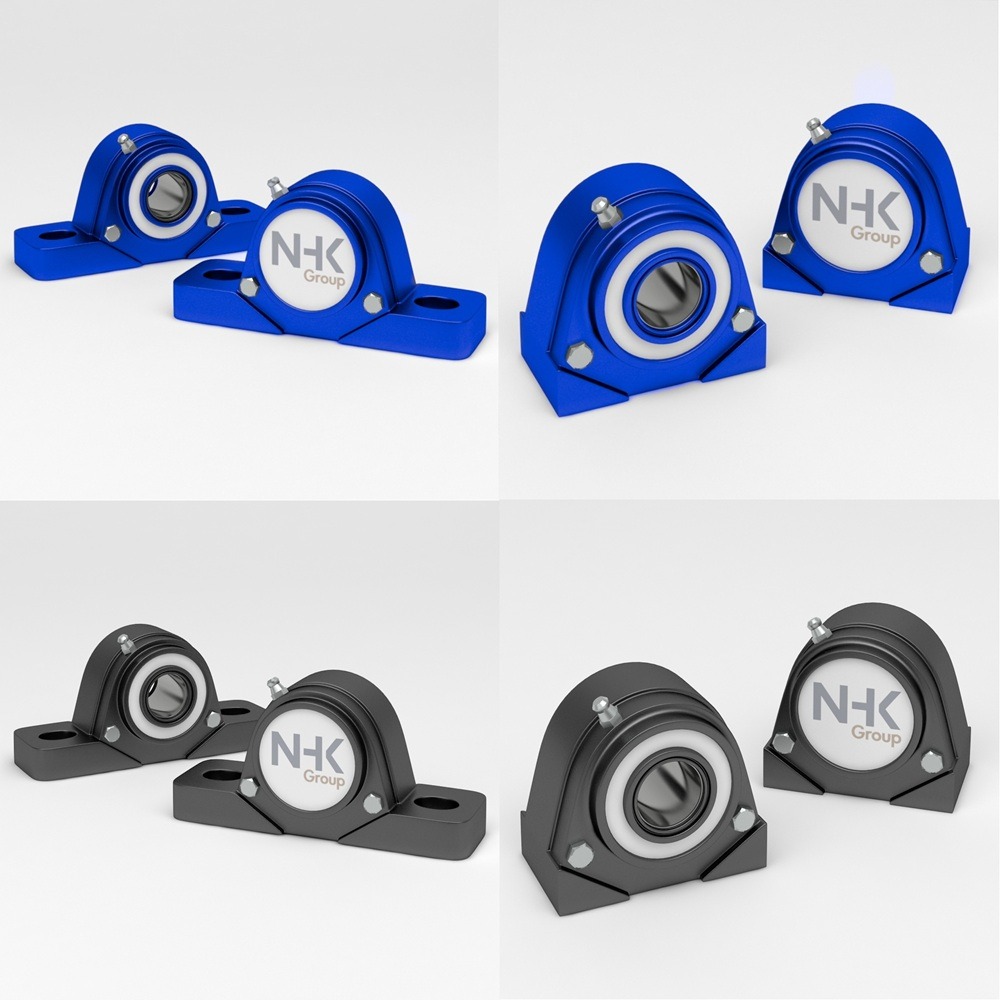

Certified IP67 Waterproof Bearing Units for Extreme Conditions

In industries where machinery operates in extreme and unforgiving environments, the reliability of components is paramount. Certified IP67 waterproof bearing units have emerged as a game-changing solution for sectors requiring durability, hygiene, and resistance to moisture, corrosion, and contaminants. These bearing units are specifically engineered to withstand harsh conditions, ensuring optimal performance, reduced maintenance costs, and extended service life. Industries such as food processing, pharmaceutical, chemical, marine, and heavy manufacturing rely on these specialized bearing units to maintain operational efficiency under extreme conditions. This article explores the usage, material selection, and the expertise behind the development of IP67 waterproof bearing units, while establishing their authoritativeness and trustworthiness in industrial applications. Certified IP67 waterproof bearing units are designed to function flawlessly in extreme conditions where exposure to water, dust, chemicals, high temperatures, and heavy loads is inevitable. These units play a crucial role in: These bearing units enhance operational reliability, minimize downtime, and support compliance with industry hygiene and safety standards. The choice of materials plays a pivotal role in ensuring long-term durability and performance in extreme conditions. Certified IP67 waterproof bearing units are commonly made from: These materials are carefully selected to withstand aggressive cleaning agents, high-pressure washdowns, and exposure to temperature fluctuations, making them ideal for food, pharmaceutical, and industrial settings. Manufacturers of IP67 waterproof bearing units leverage advanced engineering and design expertise to create components that meet the highest industry standards. The development process involves: By integrating cutting-edge design and advanced manufacturing processes, these bearing units are built to deliver unmatched reliability and longevity in demanding applications. Certified IP67 waterproof bearing units undergo strict testing and certification to meet the toughest industry demands. Key certifications include: These globally recognized certifications establish trust and confidence in the quality and reliability of IP67 waterproof bearing units across industries. The proven performance and long lifespan of IP67 waterproof bearing units reinforce their trustworthiness in extreme industrial applications. Some key benefits include: ✅ Reduced Downtime & Maintenance Costs – Eliminates failures caused by water ingress, corrosion, and contamination. By investing in certified IP67 waterproof bearing units, companies enhance productivity, minimize risks, and achieve long-term cost savings in extreme operating environments. As industries push the limits of technology and efficiency, the demand for high-performance, waterproof, and corrosion-resistant bearing solutions continues to grow. Certified IP67 waterproof bearing units offer an unparalleled combination of durability, reliability, and compliance with hygiene standards, making them the ideal choice for extreme conditions. With expert engineering, superior materials, and global certifications, these bearing units provide a long-term solution for companies seeking operational excellence and reduced maintenance costs. Whether in food processing, pharmaceuticals, marine, or industrial manufacturing, investing in IP67-certified waterproof bearings is a proactive step toward enhanced efficiency, reliability, and sustainability. For businesses operating in harsh environments, choosing trusted, certified bearing solutions ensures a competitive edge, regulatory compliance, and long-term profitability.

The Importance of Waterproof Bearing Units

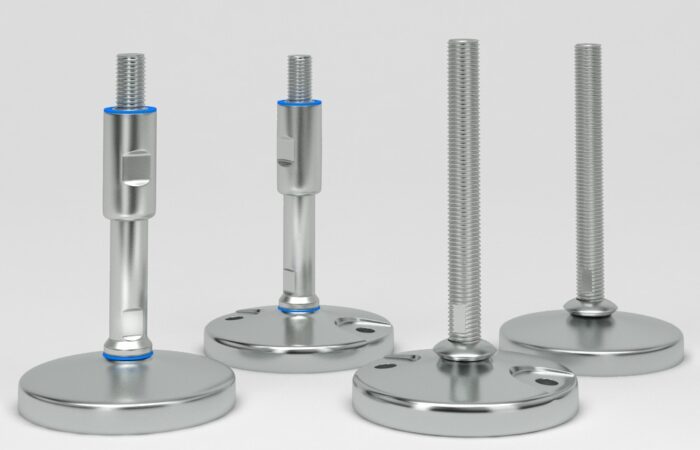

Usage of Certified IP67 Waterproof Bearing Units

Applications in Harsh Environments

Material Selection: Ensuring Durability and Performance

Corrosion-Resistant Stainless Steel Construction

Expertise in Design and Development

Precision Engineering for Maximum Protection

Authoritativeness and Compliance with Industry Standards

Certified for Extreme Conditions

Trustworthiness: A Proven Track Record of Performance

Customer Experience and Long-Term Reliability

✅ Extended Service Life – Withstands heavy loads, high temperatures, and aggressive cleaning for longer operational efficiency.

✅ Energy Efficiency – Optimized designs reduce friction and power consumption, enhancing overall equipment efficiency.

✅ Hygienic & Food-Safe Compliance – Ensures a sterile and contamination-free production process in food and pharmaceutical industries.

✅ Proven Performance in Harsh Environments – Trusted by leading manufacturers worldwide for their reliability and durability.

Future-Proofing Industrial Operations

Contact

Articles